technology Monofilament Extrusion Plant

Basic Information about Monofilament Extrusion plant

- Raw material: Plastic granules (PP, HDPE & LD)

- Finished goods : Rope, Twine and Mono yarn

- Monofilament Extrusion Pant Process 6 Step

Step 1. Mixing Unit

Different Type of Raw material like PP, HDPE, LD And Pigments (Color) Mixing Process

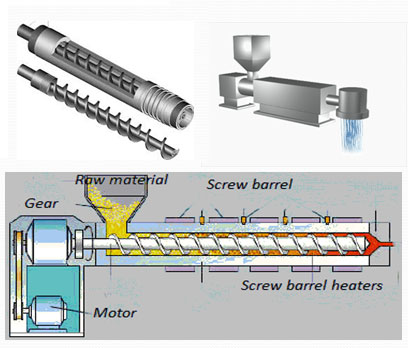

Step 2. Extrusion Unit

Raw material process in Screw barrel and Screw barrel heaters

Step 3. Die Head

Die Head With Connected Die Types of Dies: Dies are in two types, T-Die and Circular Die.

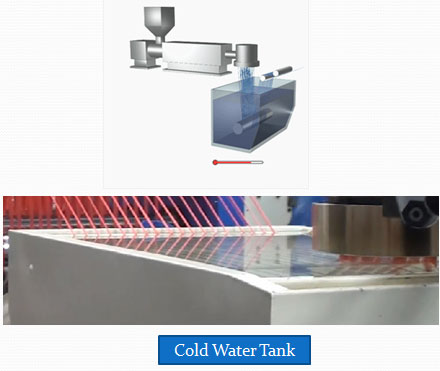

Step 4. Cooling Unit

The polymer spun from the die is put into the cooling tank to undergo the cooling process

Step 5. Starching Unit. (Elongation Unit)

Since the non-elongated filament lacks practicality due to its low strength, it should be elongated through a dry or wet process to increase its strength. Normally, it is elongated approximately 10-fold in boiling water (the temperature must be maintained above 98°C). Elongation is performed by varying the speed of the transmitting roll and the pulling roll located at the back and front of the elongation tank

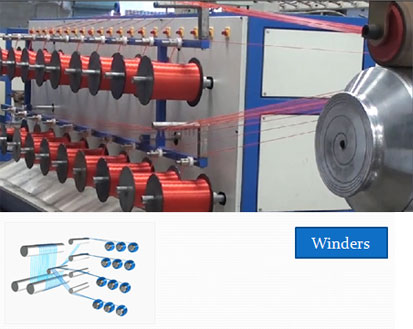

Step 6. Winding Unit

The strands of monofilament must be wound individually with fixed tension at all times. Also, the winding motor’s torque should be small enough to prevent breakage of the yarns.